SAP PP Long Term Planning (LTP)

Long Term Planning (LTP) in SAP PP is used to simulate the future demand and supply situation in all BOM levels. The main function is to check the capacity situation, material requirement and vendor ability to provide the material in desired time.

This is not an actual run but a simulative run where actual planning situation is not being affected, and we can see the capacity situation of the work centers well ahead in time. If such information is available in advance, then we can decide at an early date whether additional machines will be required to cope with capacity bottlenecks.

- LTP (Long Term Planning) is nothing but MRP run in simulation version to simulate the production plan for the future.

- It is possible to transfer the plan from simulative version to operative version “00”(actual planning) if through simulation it is found that all capacity and requirement can be fulfilled.

- The purchasing department can also utilize the outcome of long-term planning. They use the information on the future requirement quantities to estimate future purchase orders. This provides them with an opportunity to negotiate delivery schedules and contracts with vendors.

- Vendors also have an advantage from long-term planning results as they are sent a preview of future estimated purchase orders and delivery schedules.

- Generally, Planned Independent Requirement (PIR) version can be either active or inactive. For LTP planned independent version should be inactive as it is a simulative version. Only active PIR version is being taken for operative planning (MRP).

- Existing master data can be used for LTP. But to have a different master data (BOM and Routing) for LTP is also possible.

- If you want to delete the Long term planning data, then you need to delete the planning scenario and you can re-run whole cycle again with new requirement again in another inactive version.

- Long term planning data can also be utilized to transfer routing activity quantities to the respective cost centers. Controlling department can calculate activity price calculation by dividing the cost center budget value and activity quantity (calculated by LTP run) which is used for standard cost calculation.

How to Create Inactive Version of Independent Requirement in SAP

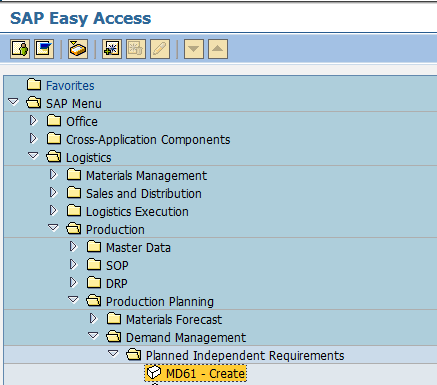

Step 1) From SAP easy access, open Transaction MD61

- Enter material code for which requirement needs to be created

- Enter Plant Code.

- Enter version as “02” which is inactive version and requirements would be considered in Long Term planning run and not MRP.

- Enter the Planning horizon dates for which demand needs to be created.

- Enter planning period as month M.

After filling in all the fields, click![]() or press Enter to go to the next screen.

or press Enter to go to the next screen.

Step 2) In this screen, we will input the requirement quantity of the material in monthly buckets.

- Version “02” and Active check box is unflagged which means it is an inactive/simulative requirement and would be considered in LTP run only.

- Enter the requirement quantity in monthly buckets.

Click![]() to save after fill all the data, the system will show message

to save after fill all the data, the system will show message![]() .

.

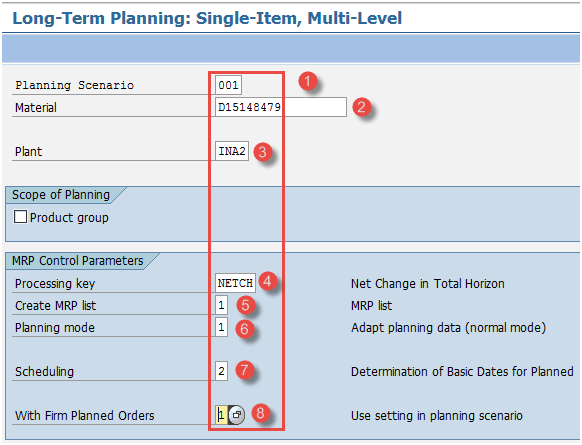

How to Create Planning Scenario in SAP PP

Planning scenario creation is required for Long term planning run. Annual simulative requirements in the form of PIR are assigned to the planning scenario.BOM selection ID is assigned to the scenario for selection of relevant BOM in LTP run. We can also include or exclude current stock , existing planned receipts from LTP run.

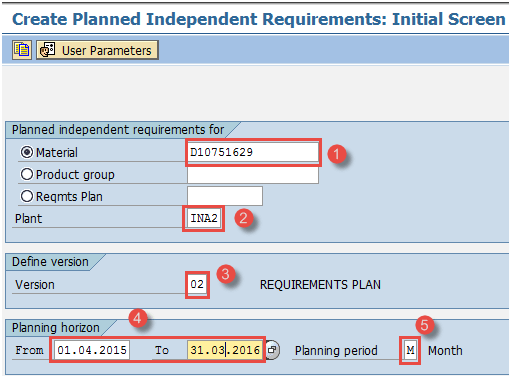

Step 1) From SAP easy access screen open Transaction MS31

- Enter Planning scenario (numeric or alphanumeric of your choice) and give the description of the scenario.

- Press enter on the keyboard to move to next screen.

Step 2) In this screen,

- Enter planning periods for which LTP run needs to take place.

- Keep Opening stock as blank which means the current stock will not be considered in LTP run.

- BOM selection id “01” means active BOM will be exploded in LTP run.

Step 3) In the same screen,

- Press “planned Independent requirement” button on top, a small pop-up window will appear.

- In the small pop up screen, enter version “02” and planning periods.

Step 4) In the same screen,

- Press “Plants” button on top and a small pop-up screen appears.

- Enter your manufacturing Plant code.

- Press button “confirm”, after verifying all the details

Step 5) In the same screen,

- Press “Release+save” button and planning file entries will be generated.

- Click “yes” in the pop-up window to release the scenario.

On clicking yes button, system will ask you to create planning file entries in online mode or background mode.

Step 6) In this screen,

- Planning file entries are generated. Click on button “immediately” to generate the entries.

Messages will be generated regarding planning file entries which means system has identified number of materials relevant for Long term planning run.

You can close this screen or can move back to easy access screen.

How to Run Long Term Planning (LTP) in SAP PP

Here is a step by step process to run long term planning in SAP PP:

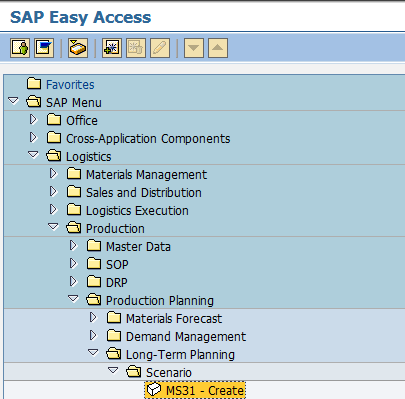

Step 1) Go to SAP Long-Term Planning option and Enter required details

In Transaction MS02, we will take LTP run:

- Enter your planning scenario.

- Enter the material code.

- Enter your manufacturing Plant code for which you want to take MRP run.

- Enter Processing key as “NETCH” ( Net change in total horizon)

- Enter “1” in MRP List and system will create MRP list similar to stock /requirement list for later analysis of previous MRP run.

- Enter Planning mode “1” as we will take LTP run.

- Enter Scheduling indicator “2” which means LTP will do lead time scheduling and consider routing times to calculate the duration of simulative planned order.

- Enter “1” to use settings from planning scenario i.e. firmed receipts will not be considered in LTP run.

Press 2 times enter from keyboard to run the LTP. System will take some time to run LTP and will throw messages regarding planning.

Step 2) Check the Procurement Proposals status

In this screen,

- Check the messages regarding number of procurement proposals created.

How to Check Stock/Requirement List in SAP

This list will show you the requirement (inactive PIR) and receipt elements like simulative planned orders for the planning scenario. This list will show all simulative data and not the real time operative data.

Step 1) In Transaction MS04

- Enter Planning scenario.

- Enter material code.

- Enter Plant code

Press enter to move to next screen.

Step 2) In this screen,

- Check whether the planned orders got generated against the PIR and check the rescheduling dates in the planned orders. These are all simulative planned orders and nothing to do with real time data.

How to Check Capacity Situation in SAP

Step 1) From SAP easy access, open transaction CM38 to check the capacity requirement at the work center ie. Work center will be loaded with simulative planned orders which has resulted in capacity requirements in terms of time.

- Enter planning scenario.

- Enter plant code.

Press enter to move to next screen

Step 2) In this screen,

- Check the capacity load at the work center which is basically ratio of capacity requirement (in hours) and available capacity (in hours).

How to Analyze Simulative Purchase Info System in SAP

LTP generates ‘planned orders’ instead of purchase requisitions and there is no ‘Source of supply’ in planned orders. However, we can see the Vendor in the Standard Information System reports.

After the LTP activity, a new version of the PURCHIS information system would be created.

Step 1) In Transaction MS70

- Enter Planning Scenario.

- Select the option “Standard/moving avg. price”, which means simulative planned orders will be evaluated at standard/moving avg price.

- Unmark “Test mode” and execute. Version info structure 001 will automatically be created.

When you press execute button, System updates the Purchase information system in version 001 with simulative purchase order quantity with value so that purchase planner can plan the raw materials for the whole year and can negotiate with the suppliers.

When you press the execute button, it will take you to the next screen.

Step 2) In Transaction MCEC, you can see the updates of purchase information system done in previous step. Order quantity can be seen vendor wise for given period. This is all done in simulation version.

- Enter Planning scenario.

- Enter your plant code.

- Enter period to analyze

Step 3) This screen will display the anticipated Purchase Quantity and value for raw materials based on simulative annual year production plan.

- Check the PO quantity and value in simulation version

Troubleshooting

- All PP master data like BOM and routing needs to be in place to effectively run Long term planning because without master data, you cannot drill down and plan to lowest level in BOM i.e. raw materials.

- Ensure to enter the PIR quantity in inactive version to avoid any conflicts in real data.

Comments