The production version is the link between a product BOM (Bill of Material) and the process Routing. It determines which alternative BOM is used together with which routing to produce a material or plan a material.

There may be different production versions based on the lot sizes and validity dates.

For example, there may be different versions if you want to produce 1 – 100 liter of paint than 100 – 1000 liter of paint, as such the different composition of BOM may be required in both cases.

- It comprises of the following data:

- The assignment of routings to the production version

- The assignment of the alternative BOM to the production version

- Production versions are used in material requirements planning (MRP), production order creation, and product costing to select the most suitable routing and the corresponding bill of material.

In order to create production version, perform the following steps-

Step 1) From SAP Easy access screen open transaction C223

- Enter Plant Code.

- Enter parent material for which production version needs to be created.

- Enter Material code.

- Input the production version code and text.

- Input the validity dates of the production version.

- Input the lot size range where it would be valid.

- Input Alternative BOM and BOM usage as “1” for production BOM.

- Enter Routing Group and Counter.

- Enter type of task list, i.e., routing.

After filling in all the fields, click ![]() or press Enter to go to the next screen.

or press Enter to go to the next screen.

Step 2) In this screen,

- Select the line of the newly created production version.

- Press “consistency check” to check whether BOM and routing are valid.

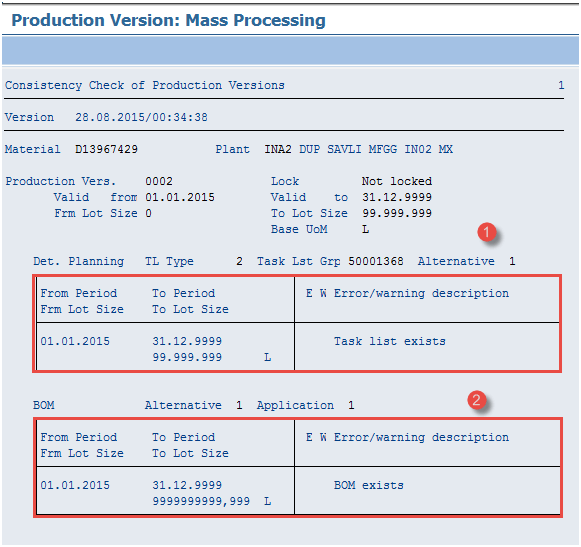

Step 3) In this screen, you can see the messages regarding the validity of BOM and routing for the material.

- Check whether task list routing exists in the validity period (01.01.2015 – 31.12.9999) and lot sizes (0 – 99999999) of the production version.

- Check whether BOM exists in the validity period (01.01.2015 – 31.12.9999) and lot sizes (0 – 9999999999999) of the production version.

Click![]() or press F3 from the keyboard to the previous screen.

or press F3 from the keyboard to the previous screen.

Step 4) In this screen, you can see the test status is indicated by green color.

- You can see the consistency check status in green color.

Click ![]() to save the new version, the system will show message ” Production version saved” at the lower left corner.

to save the new version, the system will show message ” Production version saved” at the lower left corner.

Troubleshooting

- There might be the case where in BOM and Routing are not valid in production version validity time frame. Ensure that validity period of production falls between validity period for both BOM and Routing.

Comments