The main function of capacity planning is to check the load at Work Center and do the capacity leveling i.e. balance the load at Work Center. It helps to calculate the production capacity based on the requirement of the product against the available capacity of the work center.

- MRP works with infinite capacity and creates planned orders at the Work Center at the same time since it assumes that Work Center is available all the time. So, it creates planned orders on the same date based on the requirements despite capacity shortages. You can execute those orders on that Work Center in the system which is not practically feasible in the shop floor.

- The main objective of the capacity leveling includes leveling overloads at Work Center and to achieve optimum utilization of Work Centers.

- MRP generated planned orders are converted to production orders which determine which Work Center is to be used, and accordingly the capacity requirements are generated on that Work Center.

- Capacity leveling at production order level is used for detailed production planning purpose. This is done through planning table which is used to carry detailed planning of capacity requirements over time in future.

- The capacity load needs to be checked at Work Center, and if it is overloaded, then we need to shift the orders ahead to the same Work Center or plan it in different Work Center to eliminate any capacity constraints.

How to check capacity loads

Capacity evaluation is used to analyze the load at Work Center, and you can see the load % (in step 2), available capacities and the requirements. You can also see the orders which have generated capacity requirements.

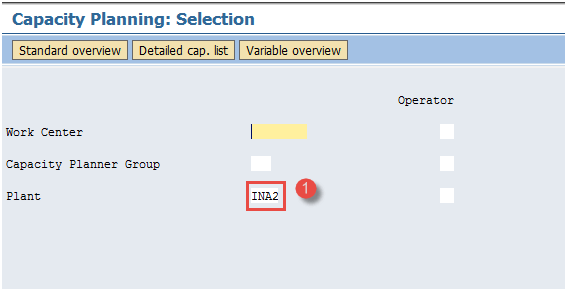

Step 1) From SAP easy access screen, open transaction CM01.

- Enter your manufacturing Plant for which you want to check capacity load.

After filling in all the fields, click![]() to go to the next screen.

to go to the next screen.

Step 2) In this screen, the capacity situation at Work Center can be seen.

- Check the capacity requirement (generated from production orders), available capacity ( determined from Work Center master data) and capacity load % at the Work Center.

How to do Capacity Levelling

Capacity leveling is done through planning table, and you need to dispatch the orders to the Work Center in the sequence in which they are supposed to be processed at shop floor.

Step 1) From SAP easy access screen, open Transaction CM21

- Input the plant for which you want to level capacity

After filling in all the fields, click execute button on top to go to the next screen.

Step 2) In this screen, you can see orders pool at the bottom and Work Center pool at the upper half of the screen in the planning table.

- Check the several orders in the orders pool.

- Check the list of Work Centers in Work Centers pool.

Step 3) In the same screen of planning table, select the data as given below.

- Select one order from orders pool.

- Click on dispatch button to assign that order to the Work Center.

Step 4) In the same screen,

- Check the dispatched order in the Work Center pool. Similarly, you can dispatch the others orders to the Work Center pool which would shift adjacent to the previously dispatched orders.

This is how you can do the capacity leveling.

Troubleshooting

- Ensure that right control key with “capacity requirement” indicator is placed in operation data in routing.

- Ensure that in the capacity tab of the Work Center, “finite scheduling” indicator in flagged.

Comments