A routing is a description of which operations or list of activities has to be carried out during the production and planning process.

It also tells what order or sequence the activities/operations needs to be carried out at work centers or machines.

- There may be several alternative routings for a product. For example, product can be manufactured on 2 manually operated machines (drilling and grinding) and simultaneously manufactured on 1 automatic machine (which has both drilling and grinding functions).In this case, Material has 2 alternative routings viz, automatic machine and manual operated machine.

- Multiple materials can follow same routing group which means a group of materials can have single routing.

- Routing is used in Production for scheduling and costing of operations for finished and semi-finished materials.

- Routing’s are also used in standard cost calculation for finished Product by calculating operational cost of finished product.

- Before creating the routing, it is mandatory that Work Center should be available in the system.

How to Create Routing

Step 1) From SAP Easy access menu, open Transaction code CA01

- Enter parent material for which routing needs to be created.

- Enter Plant Code.

- Enter the Key date (valid from date) which means that routing would be valid from that date.

After filling in all the fields, click ![]() or press Enter to go to the next screen.

or press Enter to go to the next screen.

“Header Details”

Step 2) In this step, we will maintain routing header data as given below.

- Enter Usage as “1” which is meant for Production routing and will be used in Production Order. There are other task list usages which are meant for Plant maintenance and inspection plan.

- Enter Status as “4” which is a released status. It indicates that routing is valid for material requirement planning and costing.

- Enter Lot Size as “99999999” which means that routing is valid for order quantity between 0 and 99999999.

- Press Operation button to add the sequence of operation and follow next step 3.

Some information such as Description, Group Counter and Basic Unit Measure will be populated by system automatically.

Click Operation tab and it will open “Operation Overview” screen.

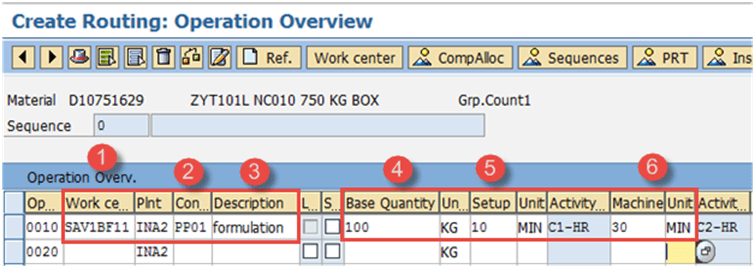

Step 3) In this step, we will maintain operation data.

- Enter Work Center code at which operation is carried out.

- Input Control Key which determines whether operation should be scheduled, costed and if auto goods receipt is possible while doing production confirmation. It is generally configured depends upon your business process.

- Input the operation description.

- Input the base quantity or output quantity of the material which indicates how much quantity of material would be produced in machine and labor time mentioned at point no. 5 & 6.

- Enter set up time in minutes required for the base quantity.

- Enter Machine time in minutes required for the base quantity.

Click ![]() to save the new routing, system will show message

to save the new routing, system will show message ![]() at the lower left corner.

at the lower left corner.

How to Change Routing

We would change routing if we have replaced old with new work centers or added one more operation to our manufacturing process. If our machine productivity is increased then we need to change the machine time or base quantity.

Step 1) From SAP Easy access menu, open Transaction CA02

- Enter parent material for which routing needs to be changed.

- Enter Plant Code.

- Key date (valid from date) which means that routing would be valid from that date is set to current date automatically.

Step 2) After filling in all the fields,click (right mark sign)![]() from the top menu to go to the next screen.

from the top menu to go to the next screen.

- Change the control key from PP01 (without auto GR indicator) to PP03 (Auto GR indicator).Auto Goods Receipt means when you do production confirmation, Goods receipt of material will happen automatically.

- Change the Machine time.

After finishing all modifications, click ![]() to save Routing.

to save Routing.

How to display Routing

To display the routing we will follow the following steps.

Step 1) From SAP Easy access screen open in transaction CA03

- Enter parent material for which routing needs to be displayed.

- Enter Plant Code.

- Key date (valid from date) which means that routing would be valid from that date is set to current date automatically.

After filling in all the fields, click![]() sign from top menu to go to the next screen and display the routing.

sign from top menu to go to the next screen and display the routing.

Step 2) In this screen we will see, how the operation data of routing is displayed.

- The screen will display the operation data of routing like – operation carried out by the work center, base quantity (100 EA), set up time (10 minutes) and machine time (35 minutes.)

Troubleshooting

- There might be the case wherein material master record does not exist. For this, you need to create the material master for the material before creating routing.

- Some users might get error “work center does not exist”. In this case, work center should be created beforehand.

Comments